Standard sandblasters vs. Instant-Off sandblasters

One question about our sandblasters we get a lot is: what does “Instant-Off” mean?

The answer is: it refers to the flow of sandblasting media from the tank out through the handpiece nozzle.

For clarity: all our “Master” models have instant-off functionality.

On an Instant-Off (I/O) model, the media stops immediately once you release the foot pedal. On our standard models, the media bleeds off for a few seconds.

Why does it do this?

The bleed-off is caused by the media tank depressurizing.

On our standard sandblaster models, the tank in use depressurizes each time you release the foot pedal. On the I/O models, the tank only depressurizes once you flip the switch to the OFF position.

What are the pros and cons of each kind?

Standard sandblaster pros:

- Lower upfront cost

- Less maintenance required

Standard sandblaster cons:

- Less precision

- More frequent cleanup

- More frequent media tank refills

Instant-Off sandblaster pros:

- Greater precision/control

- Less mess

- Less frequent media tank refills

Instant-Off sandblaster cons:

- Higher upfront cost

- More maintenance required

Who should get a regular sandblaster?

- General technicians

- Dental/orthodontic technicians

- Surface preparators

- Anyone removing burrs or debris from durable parts

- Anyone cleaning parts or surfaces by blasting

Who should get an Instant-Off sandblaster?

- Artists and artisans

- Restoration specialists

- Fossil preparators

- Dentists, doctors, or other healthcare specialists

- Anyone removing small or detailed segments of coating or matrix

- Anyone removing burrs or debris from sensitive instruments or parts

Maintenance for Instant-Off sandblasters

With our “Master” or Instant-Off sandblasters, the additional maintenance is very specific and very important.

The pinch valve that makes the functionality possible is where the handpiece tubing will get the most wear. The effect is like chewing on a straw — you’ll cause distortion and eventually holes. To prevent prematurely wearing out, regularly move that tubing back and forth through the pinch valve casing.

Additionally, as a general practice, it’s important to keep the blaster in the OFF position when it’s not in use. Leaving it in the ON position will continue wearing out that same spot on the tubing.

It’s also a good practice to switch to the OFF position when changing between tanks.

Pro tip…

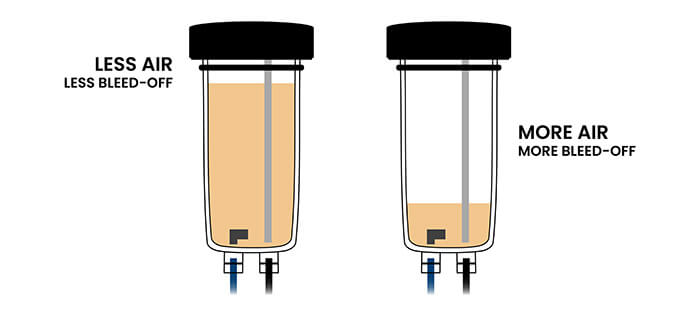

You can reduce the amount of bleed-off during depressurization by keeping the media tanks as full as you can. When there’s less blasting media in the tanks, that means there’s more air…and more pressure to release, which of course takes more time. With a longer depressurization, more media will flow out.

This also helps cut down the time to come up to pressure on standard units (since they have to re-pressurize to get the media flowing) so proper blasting starts sooner.

Instant-Off Dental Sandblasters:

-

SandStorm Mobile I/O – 80141$541.06View Details

SandStorm Mobile I/O – 80141$541.06View Details -

SandStorm Prestige I/O – 80170$1,513.88View Details

SandStorm Prestige I/O – 80170$1,513.88View Details

Instant-Off Industrial Sandblasters

-

Master Mobile Problast – 80031$541.06View Details

Master Mobile Problast – 80031$541.06View Details -

Master Mobile Problast – Glass Etcher$549.99View Details

Master Mobile Problast – Glass Etcher$549.99View Details -

Master Problast 2 – 80355$1,099.00View Details

Master Problast 2 – 80355$1,099.00View Details -

Master Problast – 80020$1,286.63View Details

Master Problast – 80020$1,286.63View Details -

Master Problast 3 – 80060$1,513.88View Details

Master Problast 3 – 80060$1,513.88View Details -

Master Problast 3 ESD – 80056$2,795.00View Details

Master Problast 3 ESD – 80056$2,795.00View Details