Abrasive Sandblasting Media

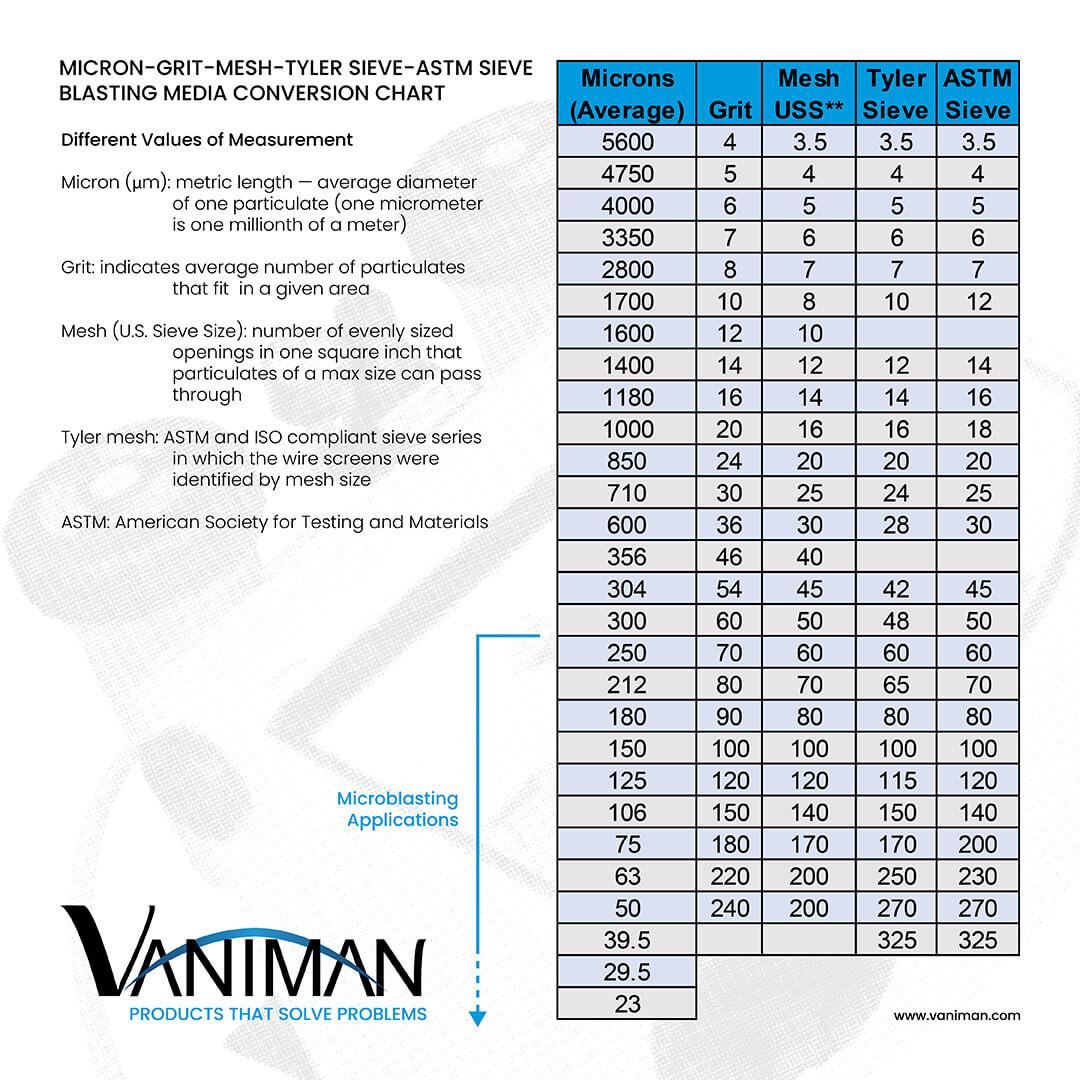

High-quality abrasive media for micro sandblasters. We offer many different types of sand blasting media including aluminum oxide, glass beads, sodium bicarbonate, and walnut shell sand for many blast applications. Our abrasive media is graded to ANSI B71.12 and FEPA specifications. Bead sizes range from 360 grit (25 Micron) to 63 grit (250 Micron).

Scroll further down to see all media for sale or click the links below.

Aluminum Oxide | Glass Bead | Sodium Bicarbonate | Walnut Shell

Sandblasting Media Selection Guide

Choosing the correct sandblasting sand or media for a sandblaster is extremely important as each type of media has its own characteristics. Use the sections below for more detailed information to select the ideal media for your application.

(More details found here: The Vaniman Guide to Microabrasive Sandblasting Media)

Sandblasting Media Specifications

Showing 1–12 of 23 results

-

Aluminum Oxide Sandblasting Media 100 Micron (120 Grit) – 15lbs – 97923

$55.78 View DetailsAdd to cart -

Aluminum Oxide Sandblasting Media 100 Micron (120 Grit) – 55Lbs – 98202

$149.19 View DetailsAdd to cart -

Aluminum Oxide Sandblasting Media 100 Micron (120 Grit) – Single Tank Fill – 97937

$21.75 View DetailsAdd to cart -

Aluminum Oxide Sandblasting Media 25 Micron (360 Grit) – 15lbs – 97921

$104.60 View DetailsAdd to cart -

Aluminum Oxide Sandblasting Media 25 Micron (360 Grit) – 55Lbs – 98201

$312.20 View DetailsAdd to cart -

Aluminum Oxide Sandblasting Media 25 Micron (360 Grit) – Single Tank Fill – 97935

$43.47 View DetailsAdd to cart -

Aluminum Oxide Sandblasting Media 250 Micron (60 Grit) – 15lbs – 97924

$56.87 View DetailsAdd to cart -

Aluminum Oxide Sandblasting Media 250 Micron (60 Grit) – 55Lbs – 98203

$149.19 View DetailsAdd to cart -

Aluminum Oxide Sandblasting Media 250 Micron (60 Grit) – Single Tank Fill – 97938

$21.75 View DetailsAdd to cart -

Aluminum Oxide Sandblasting Media 50 Micron (240 Grit) – 15lbs – 97922

$55.78 View DetailsAdd to cart -

Aluminum Oxide Sandblasting Media 50 Micron (240 Grit) – 50-55 lbs. – 97927

$156.30 View DetailsAdd to cart -

Aluminum Oxide Sandblasting Media 50 Micron (240 Grit) – Single Tank Fill – 97936

$21.75 View DetailsAdd to cart

Showing 1–12 of 23 results

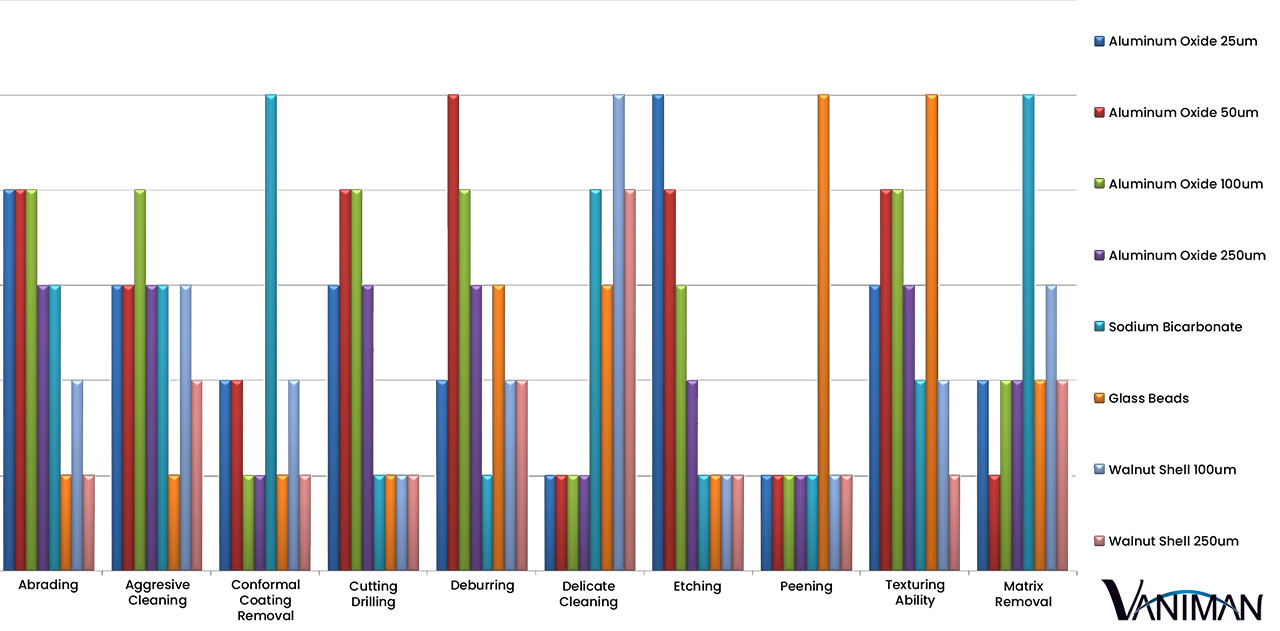

Use this abrasive blast media chart to help select the ideal media type and size for your application.

Use this abrasive blast media chart to help select the ideal media type and size for your application.