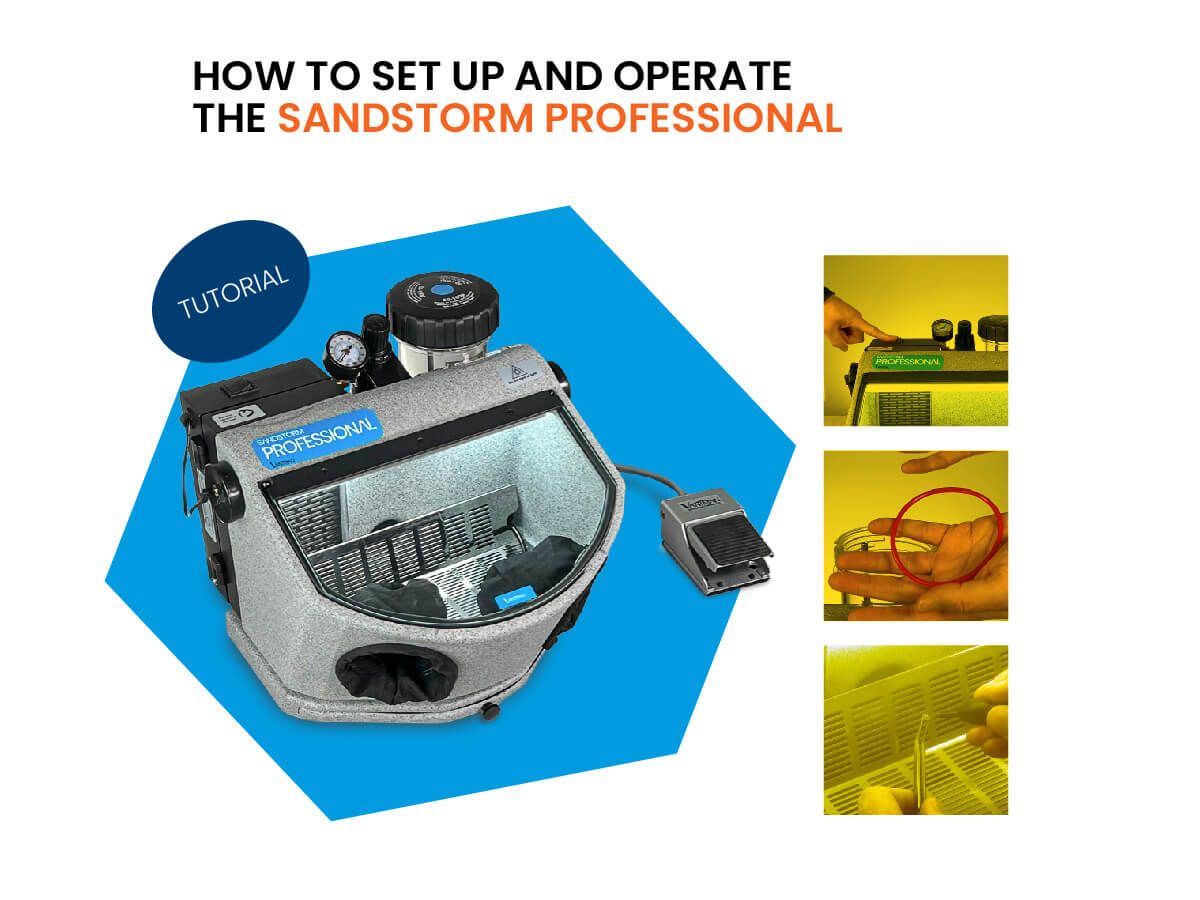

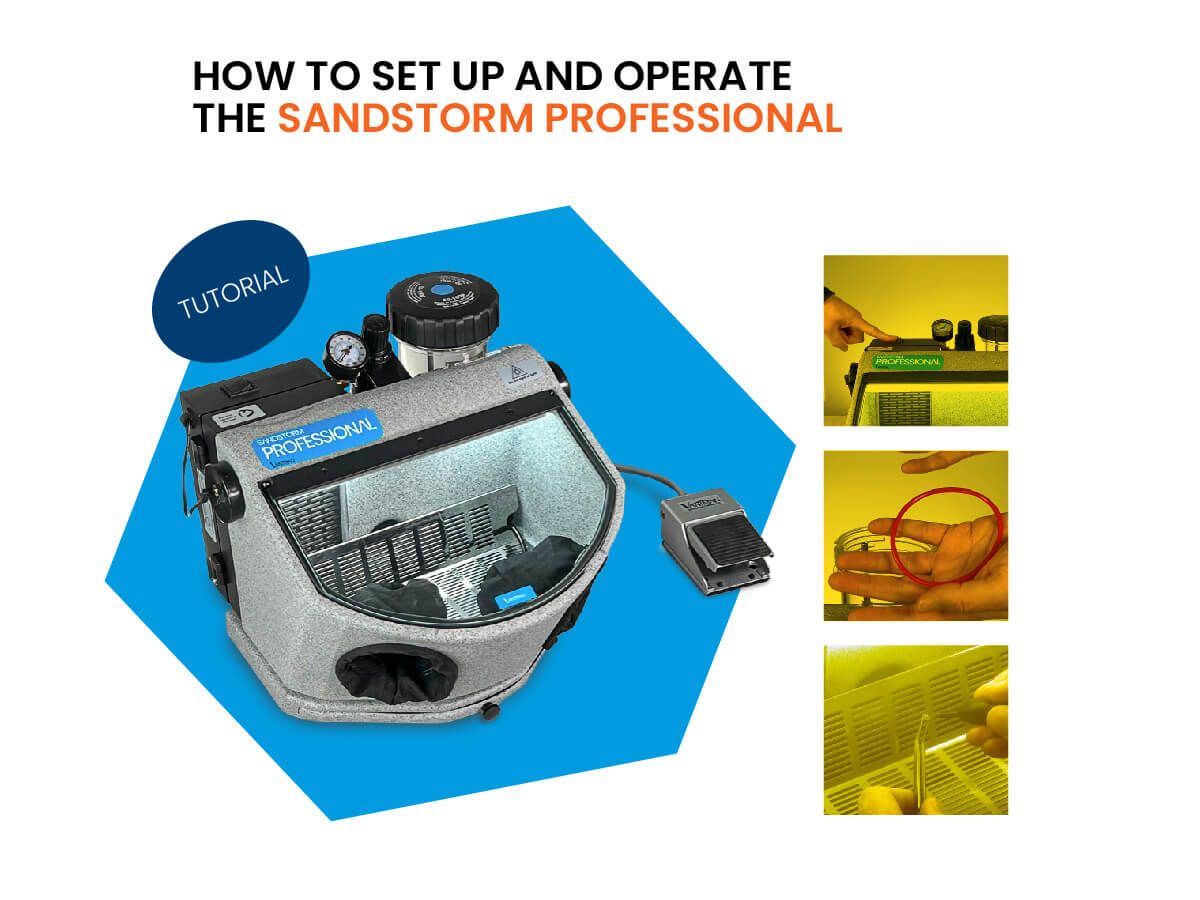

This tutorial walks you through proper setup and usage of the Vaniman SandStorm Professional, a microabrasive sandblaster with a built-in dust fan and filter for light use.

Vaniman content specifically about microabrasive sandblasters and their myriad applications for a variety of industries.

This tutorial walks you through proper setup and usage of the Vaniman SandStorm Professional, a microabrasive sandblaster with a built-in dust fan and filter for light use.

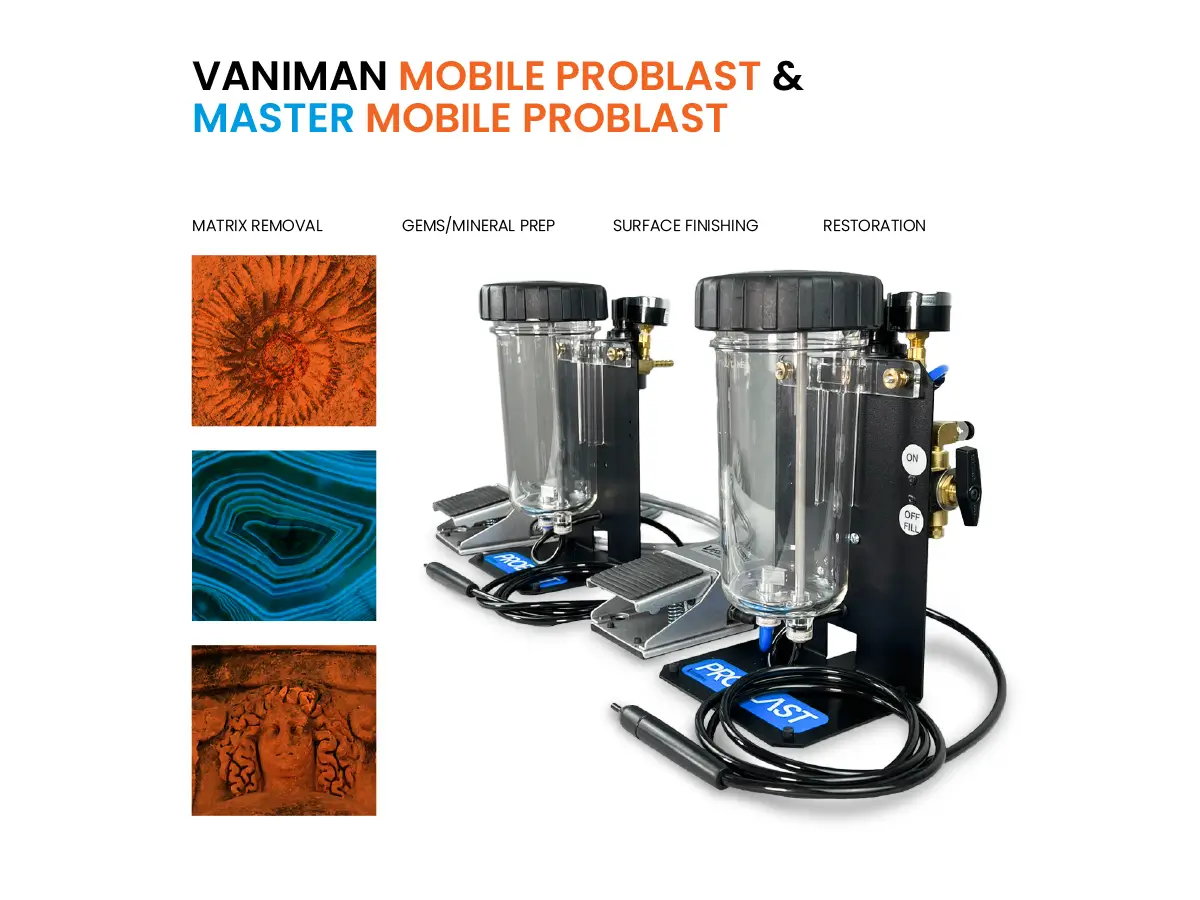

Vaniman’s Mobile Problast is the perfect micro sandblaster for fossil preparation and matrix removal, glass etching and carving, tool cleaning, post-print parts processing, polishing, peening, deburring, deoxidizing, and tons of other uses.

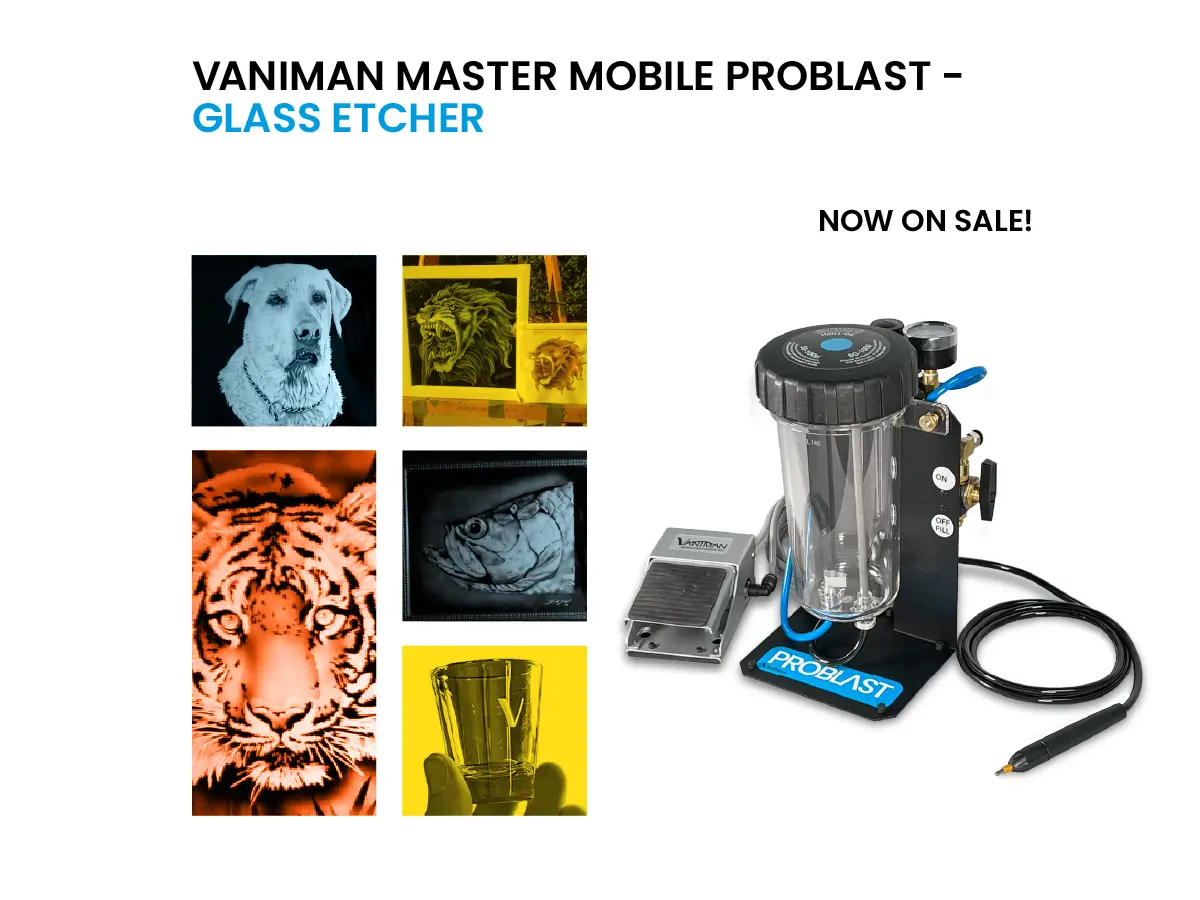

Need a great gift for the artist in your life? You’re in luck — the Vaniman Master Mobile Problast – Glass Etcher is on sale now!

Earlier this year we connected with Morne Mamlambo of Mamlambo Fossils — he’d been wanting to try a sandblaster for a tricky crab fossil he’d been working on.

We’ve compiled all the latest technical resources and standards to make your next PCB rework and repair job a breeze whether you’re working with Acrylic, Epoxy, Silicone, Parylene or Urethane. Enjoy!

One question about our sandblasters we get a lot is: what does “Instant-Off” mean?

With an available Instant-Off model variant, the SandStorm Prestige gives you three tanks for three different media options in a large steel cabinet. This blaster is for medium to heavy use in labs with a variety of applications.

We compare orthodontic sandblasters to intraoral sandblasters/microetchers to see which is ideal for surface prep and adhesive removal.

Here are our top five maintenance tips for keeping your sandblaster (and your sanity) in good condition. Make sure to keep on top of these!

Avoid these two most common causes of blockage in sandblasting systems.