So you’re designing a dental lab and you’ve thought of everything except dust collection…

Beware. When dust collection is an afterthought, labs get pretty messy with piping, and pretty expensive with equipment. Unplanned approaches to dust collection often result in costly corrections down the road.

And the problems dust creates can get out of hand quickly. Increased cleaning bills, frequent repairs, and even serious chronic health problems can arise.

But with proper dust collection and efficient plumbing, you can keep your staff safe and your costs down.

The key is thinking about dust collection as a system rather than a random collection of units.

In a lab, dental vacuum system piping design matters quite a lot.

There are a few different ways you can optimize your dental lab dust collection. Let us break it down for you. Read this practical guide to dental lab suction design for what to consider about:

Dust collector considerations

At the core of any dust collection system are the dust collectors themselves. Choosing the right dental lab suction units from the outset is crucial.

Vacuums vary in size. They vary in suction power. They vary from single-station units to fully centralized multi-station systems.

Here’s what you’ll need to consider:

- How many stations do you need to serve?

- How many stations can be active at once?

- Where are the stations located?

- Will each station have independent plumbing?

- How much power would multiple stations need?

- How easy will it be to maintain a dust collector once it’s in place?

There are many factors that can affect your decisions, but these are the most important.

How many stations…

Some dust collectors are designed for one station, and some are designed for more. You can pick what kind of unit you’d need based on:

- How many stations CAN I connect to one unit?

- How many stations connected to the same unit could operate at the same time?

What kind of dust…

You will also need to consider what kind of dust each station will create.

- What materials are you working? Gypsum? Zironia? Other?

- Will there be sandblasting abrasive media?

Where are stations located…

Different labs have different setups. Some stations are flush against walls, some are in the middle of a room. You’ll have techs working at benches, countertops, islands, etc. It’s important to establish the layout before choosing dust collectors. (NB: sometimes lab owners choose their dust collectors and then create a layout based around that — this is also perfectly fine if you are sure about your approach.)

You’ll also need to consider how the piping will fit, and whether stations share piping.

How to maintain…

Accessibility is key to easy maintenance. If you can’t get to the dust collector, you can’t swap out its filter bag or adjust any settings. Will your dust collectors be accessible where they are placed?

Vaniman dental lab suction units…

The kind of dust and the volume you expect should inform what kind of dust collector(s) you should get. At Vaniman, we have a variety of different dental dust collectors:

- SandVac: single station, designed to collect sandblasting abrasive media.

- Vanguard line: single station or two station units, designed to collect acrylic, gypsum, die-stone, alloy, quartz, zirconia, and ceramics, but not for abrasive media.

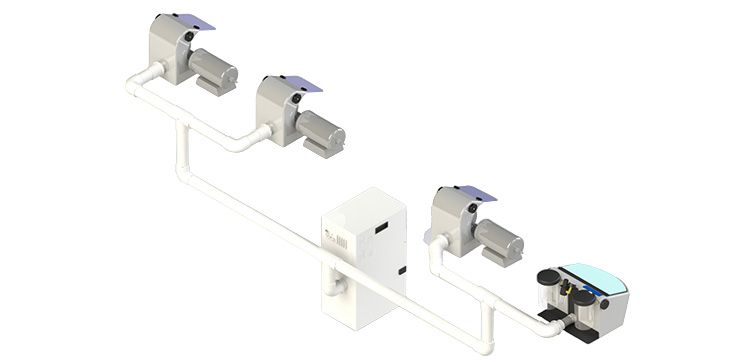

- StoneVac line: powerful single station or multiple (up to four) stations or up to two dental mills, can safely collect all dry dental lab materials (including zirconia and abrasives).

- V6 SE: multiple (up to six) stations or up to four dental mills, can safely collect all dry dental lab materials (including zirconia and abrasives).

For smaller labs, the best setup may involve single station dust collectors next to or under stations. For other labs, the best bet may be a combination of single- and multiple-station dust collectors.

For larger labs considering centralized suction instead of single-station units, the V6 is our recommended choice. If there are more than six stations that need suction, a centralized cluster of V6 units provides the suction power needed. This setup eliminates most of the inconveniences and costs of one giant central dental vacuum system. Simply add another V6 unit for every six stations requiring “at once” suction.

Read more about the next-generation V6 SE Multi-Station Dust Collector here.

If the proper arrangement of dust collectors gets too complex, don’t worry — Vaniman is here to help. Our Design Center team offers consultation and even design for suction in labs, COMPLETELY FREE OF CHARGE.

Get started with a free lab suction design here.

Valve and switch considerations

Once you have an idea of which dust collectors you’ll need, your next step is to determine valving.

Your system needs to stay sealed. You’ll need valves to open and close the suction flow to each of the workstations. Without valves, you’ll have a permanent leak in your system that will kill off the available suction to all the other workstations.

Valves and switches keep your air flow optimized and cut waste. Here’s what you’ll need to consider:

- How many stations does each dust collector serve?

- How many stations will be used at once? (In other words: how many stations will need to stay closed while another is in use?)

- How convenient will it be to open/close suction at each station?

- How exactly will you open/close those stations? And who will be doing the opening/closing?

How many stations…

At any given station, you could theoretically keep suction airways open or closed. For stations using the same dust collector, all airways should close — except for the one(s) in use at any given time. The more open airways, the harder the dust collector has to work to provide the same amount of suction.

There are manual valves to open or close the entrance, and ways to remotely activate a shutoff valve. Vaniman has a variety of options to help with any of these; more on this below.

How convenient will it be…

Ease of operation is key. If techs can’t easily turn it on or off, that’s likely to affect production and morale.

At every station that needs to be able to close off, you’ll need to make a choice whether to go with a manual shutoff or a smart valve of some kind. There are pros and cons to each.

Manual valves…

Manual valves need a technician to intentionally operate the valve. That means the valve will need to be within arm’s reach, easily accessible. It also means there’s no connection between the dust collector and the valve at the workstation. You’d have to turn the dust collector on and off independently.

If you’ve got one dust collector serving two stations, you could use a variety of open/shut valve options for both of those stations. If only one of those stations is typically in use at a time, consider a manual 2-Station Selector Valve Tee rather than two on/off valves. The benefits are:

- It’s a single piece to add into your plumbing rather than two pieces.

- It allows for complete closure to one while the other is in use.

- It also allows for both to be open if they are both in use.

Smart valves…

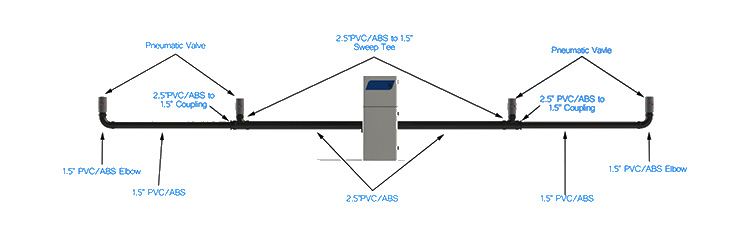

Smart valves, on the other hand, solve a lot of potential problems. Vaniman’s Pneumatic Valves open and shut with an internal air bladder. (An additional airline is needed, as well as a regulator to keep that airline to 10-15 PSI max.)

Our Pneumatic Valves can work independently of dust collector operation (via a Manual Control Switch). They may also work via a combining box and Smart Switch that activates the valve and the dust collector at the same time.

We also offer Smart AutoPilot technology. A tech can activate both the Pneumatic Valve and the dust collector automatically using their handpiece or a small lathe. When the tech stops using the handpiece, there’s a few extra seconds of suction, then the dust collector shuts off and the valve closes again — all automatically.

Pipes/plumbing considerations

Proper airflow is a major concern when designing a proper suction system. Plumbing has a lot to do with that.

Use too small of a pipe to your workstations, and your suction will be limited (think of using a stir-straw to sip on a milkshake). Go too big, and the farthest stations from the dust collector won’t get enough power.

Beyond your workstations being open or closed, you also need to consider:

- What kind of air plumbing will be used? (Flexible hoses, or hard PVC pipes?)

- How many stations are interconnected?

- How far away are the stations from the dust collector?

What kind of plumbing…

The goal should be to provide an equal amount of suction to each station while they are operating.

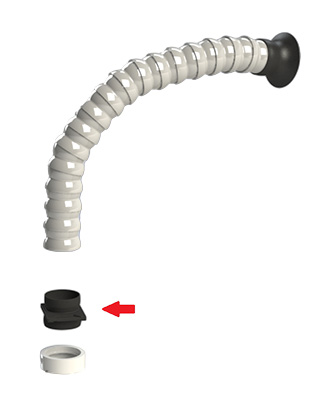

Flexible hoses work well for:

- Short distances (six feet or less)

- Single station setups

- When equipment needs to be movable

All Vaniman dust collectors come with flexible hoses (either 1.5” or 2.5” diameter, depending on the model). We also offer a variety of adapters to ensure the hoses connect and seal properly.

Hard PVC pipes work well for:

- Longer distances

- Multi-station setups

- When equipment is stationary

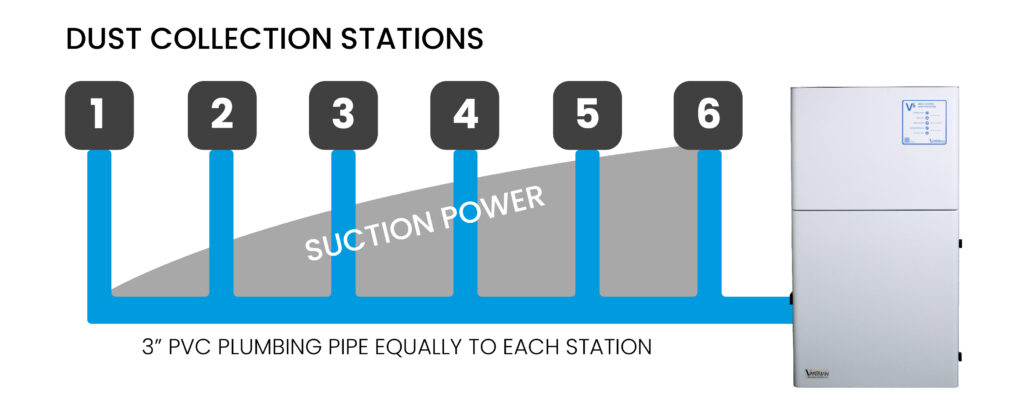

PVC pipes can better provide equal suction to each station while they operate.

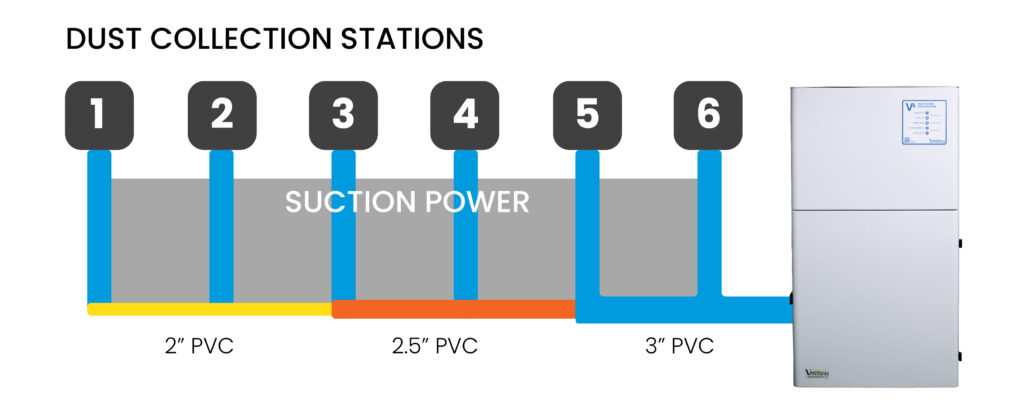

Take, for example, a six-station setup with all the stations next to each other in a line. If you run the same size trunk line (the main supply pipe) and “T” off to each station with the same sized piping, station six will hog most of the suction. Meanwhile, station number one — all the way at the end — will get little to no suction.

The solution isn’t to get a bigger dust collector. It’s to neck down your pipes in the right areas so the suction can be equally distributed.

In this six-station setup, if you decrease your trunk line from 3″ to 2.5″ after station five, then again down to 2″ after station three, you’ll be able to distribute the suction more equally. Since the stations further away from the dust collector use smaller piping, the air flow in the system is better balanced.

Of course, each dental lab will have its own unique design and approach. But the concept is the same: maintain a proper balance throughout the system.

It’s important to note that the bench design you choose will also play a big role in your dental vacuum system piping design. Benches or workstations that you can modify are usually best, since you’ll have more flexibility when setting up equipment.

Vaniman’s free dental lab suction design service

Avoid sloppy suction in your lab. There are smart ways to design in the space you have.

If you need a custom dental lab suction design, contact us about our free Design Center service. One of our engineers will help you design your lab suction system based on your station setup and layout. We’ll provide you with detailed diagrams, descriptions, 3D renderings, and a precise list of everything you need to complete your own custom setup.

Simply fill out our questionnaire form below to get started.

Nice illustrations! Very helpful.

Thank you David! We’re happy to help! Let us know if you have any questions at all. Have a great day!