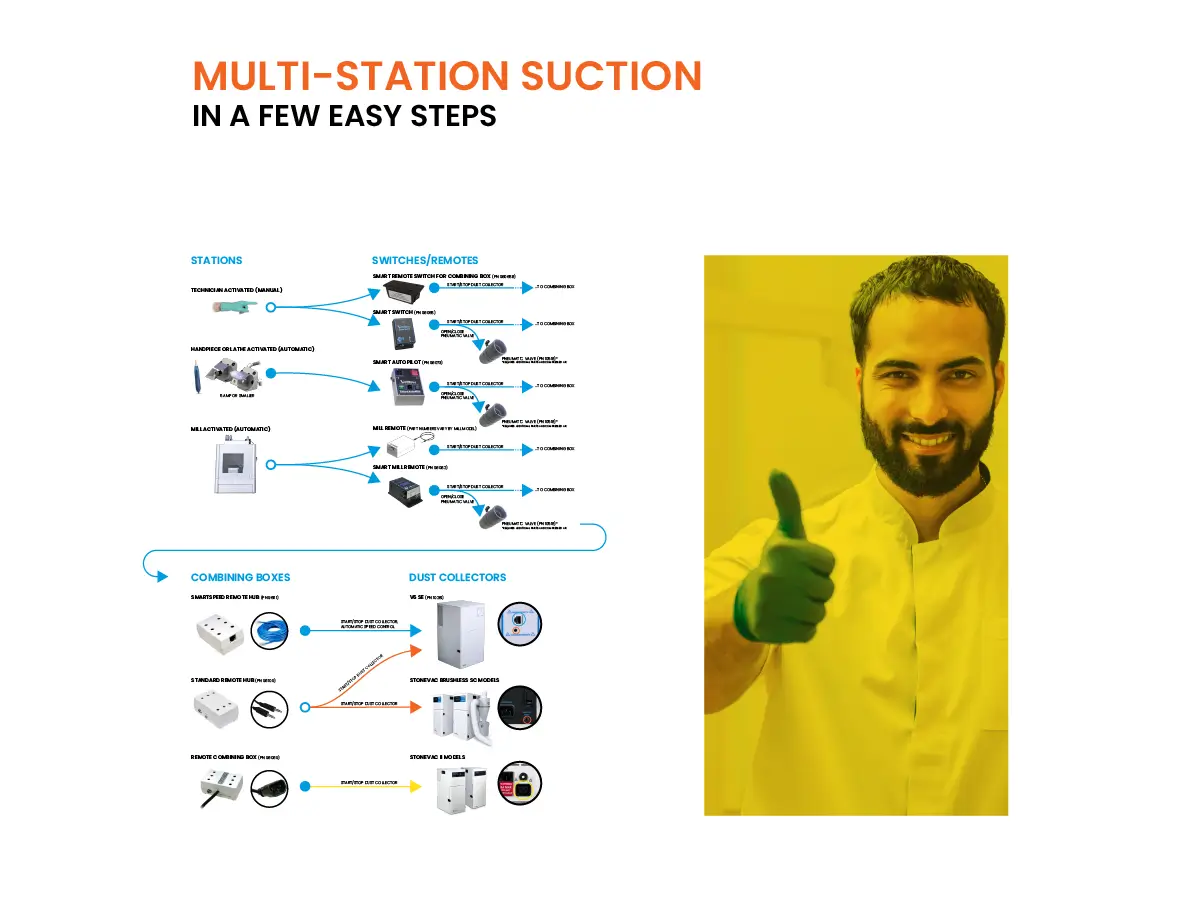

When our team designs a custom dust collection system for a dental lab, office, or any other facility in any industry, we follow a process.

The Vaniman Smart Suction System™ connects your work stations to a centralized dust collection unit or cluster of units. It includes a series of switches to control the units and valves to keep suction pressure balanced and efficient.

Often, customers want to start designing their system by picking out a dust collector, and determining what switches or accessories go with it.

That’s actually backwards. To design the most effective solution, you start with the stations. Determine what’s happening at the station, and that will inform the connections, and ultimately determine the model of dust collector that is best suited for the system.

The simple way to think of it is:

Making suction work for you – the simple version

Stations (Switch or Remote):

- Each working area (station) needs a switch or remote to control suction.

Combining Box:

- Imagine this like a traffic hub. All switches or remotes from the stations connect here.

Dust Collector:

- The combining box then connects to the dust collector, the big machine that takes care of all the suction.

Breaking it down even more

For multiple stations:

- If you have one dust collector for many stations, you’ll need switches or remotes at each station.

Different jobs, different needs:

- Identify what happens at each station – grinding, finishing, sandblasting, or milling. This helps pick the right switch or remote.

Closing off stations:

- Think of each station like a room. Use a valve (either manual or Pneumatic Valves) to ‘close the door’ when you don’t need suction.

About Pneumatic Valves (PN 10518):

- These valves work with specific switches. They open and shut automatically. We’ll explain more about these later.

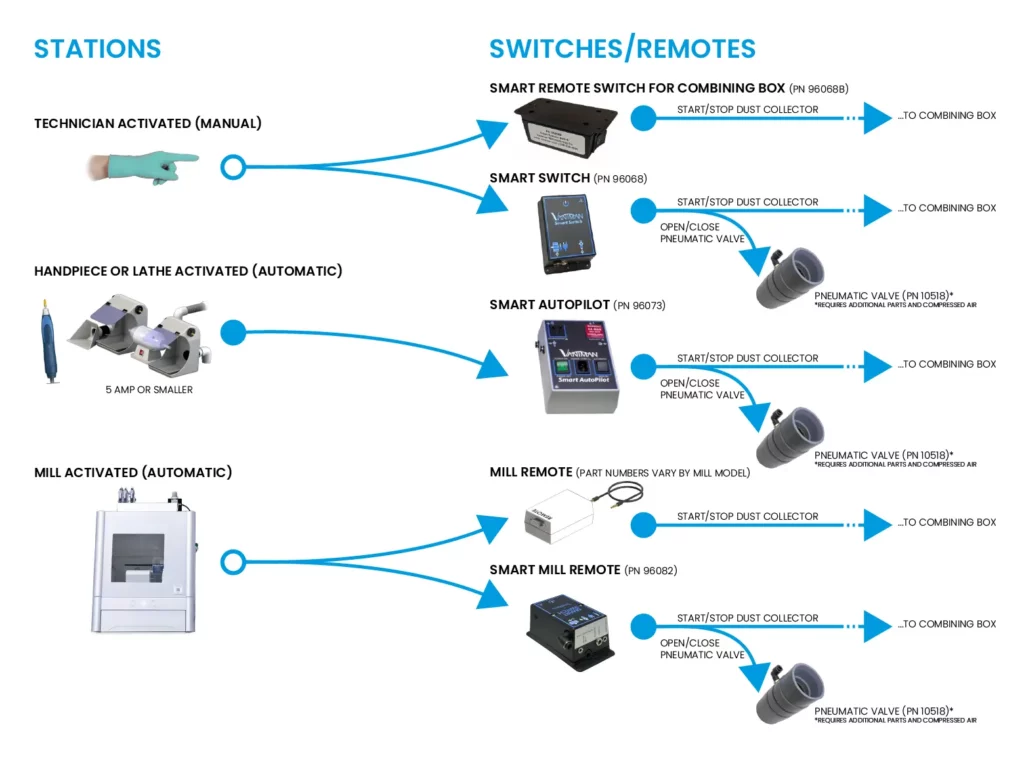

Switches/remotes (basics)

When it comes to making the dust collector work, there are different options for switches and remotes.

For manual control (switches):

- Smart Switch (PN 96068):

- This switch is placed at the station.

- Connects to any combining box.

- Starts or stops the dust collector.

- Opens or closes a special valve (Pneumatic Valve).

- Smart Remote Switch for Combining Box (PN 96068B):

- Similar to the Smart Switch.

- Ideal for stations using manual valves.

- Does not control the Pneumatic Valve.

For automatic activation (Smart Autopilot):

- If you want the dust collector to turn on automatically when a technician uses a handpiece or a small lathe (5 Amps or less), use the Smart Autopilot (PN 96073).

- This device:

- Starts and stops the dust collector automatically.

- Opens and closes a Pneumatic Valve.

For dental mill:

- Connect a Mill Remote (part numbers vary by mill model) to:

- Automatically start and stop the dust collector when the mill is in use

- Use a Smart Mill Remote (PN 96082) to:

- Start/stop the dust collector via the combining box.

- Open/close a Pneumatic Valve.

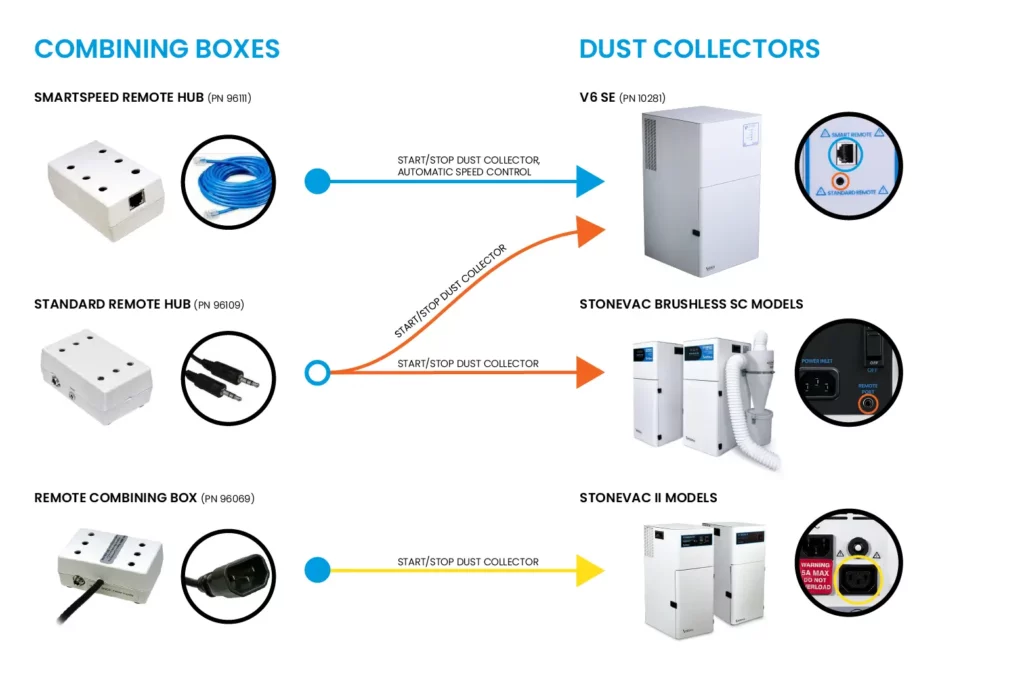

Combining boxes

Our combining boxes are hubs for remote connections that then connect to the dust collector. These can accept up to six remotes. Each dust collector has 1 remote port input, and the combining box acts as an expander for that port.

The SmartSpeed Remote Hub (PN 96111):

- Connects only to the V6 SE (for now).

- This is the combining box you need to utilize the SmartSpeed control capability of the V6. The SmartSpeed Remote Hub tells the dust collector how many remotes are on at a time, and the dust collector will adjust its speed to meet the demand.

The Standard Remote Hub (PN 96109):

- Connects to either the V6 or a StoneVac brushless motor model (the StoneVac Brushless SC [PN 10240], the StoneVac Mill Sync [PN 11060], or the StoneVac AM for 3D Printers [PN 11051]).

- With this combining box, the switches will start or stop the dust collector, but no automatic speed control is available.

The Remote Combining Box (PN 96069):

- Connects to a StoneVac II (PN 10201) or a StoneVac II+ (PN 10202).

- Again, this will start or stop the dust collector, but no automatic speed control is available (as these units are single-speed only).

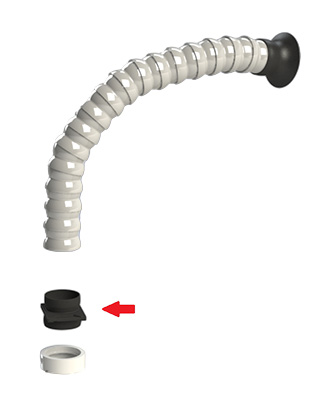

Valves for closing off stations

As mentioned above, the stations should be closed by some kind of valve when they are not in use. Otherwise, the pressure escapes and the dust collector loses efficiency. We offer a couple different ways to keep those stations closed. One is manually, with the Manual Shut Off Suction Valve (PN VMC-A380), the 2 Station Selector Valve T (PN 10510), or, for the Flex Hose Kit, our Flex Hose Shut Off Valve (PN 96062).

The other way is with the Pneumatic Valves mentioned above, which can be opened or closed with a separate Manual Control Switch (PN 10522), or in time with the dust collector via the Smart Switch, Smart Autopilot, or Smart Mill Remote. (Please note that Pneumatic Valves require compressed air, a regulator (PSI 15 max), and additional tubing.)

After all the station details have been worked out, deciding on a dust collector that best fits your needs is much easier!

Design Center

We certainly hope you’re less confused now than before, but we understand that a complete suction setup is still quite a complex thing to put together.

Vaniman can help. Our Design Center team can design your complete suction setup for your unique space, complete with 3D renderings so you can see what you’re building, as well as a complete bill of materials and installation instructions (which you can hand off to your contractor if you’re building out the space).

This custom design service is completely FREE.

To get the process started, simply fill out the form below and one of our product specialists will get in touch with you as soon as possible!

Related:

Quick reference: one-sheet PDF