How to choose a micro sandblaster for abrasive metal finishing.

Micro-abrasive sandblasters are preferred for metal finishing and surfacing applications over other post-processing methods because they are more precise, accurate, and customizable. This is accomplished by testing different blasting materials (size and type), blasting tips, and air pressures to get the desired results. Once the micro-abrasive sandblaster is fine-tuned the process will be quick and painless. A micro-abrasive sandblaster is a flexible tool that can be tweaked and adjusted based on different applications.

When choosing the right micro-abrasive sandblaster for you, consider the following:

- Purpose of Metal Finish

- Type of Metal

- Determine Which Blasting Material to Use

- Choosing Cabinet Size Based on Application

- Instant Off

- Number of Tanks

- Dust Collection

Purpose of Sandblasting Metal Finishing

Clearly defining your objectives for using a micro-abrasive sandblaster and knowing how it will affect the surface of your part is crucial to any successful metal finishing application. Most blasting media removes a thin layer of metal, which means it can affect your tolerances if you’re not careful. Here’s a list of common uses for a micro-abrasive sandblaster and how the blasting media affects the surface:

- Surface cleaning/polishing: Removes little to no metal.

- Removing machine lines: Removes a thin layer of material. It’s easy to remove too much and affect tolerances.

- Deburring: The blasting media will cut through the bur to remove it. As a result, some of the surface around the bur can be affected.

- Surface abrasion for adhesion: Removes a layer of material and creates a rough surface.

- Matte finish: Flattens or smooths out the surface. Little to no material is removed.

Type of Metal

The type of metal plays a crucial role in desired finished because metals vary in hardness. Softer metals like aluminum and copper are great for micro-abrasive sand blasters because a wider range of materials can be used.

Determine Which Abrasive Blasting Media To Use

Now you should have properly defined your purpose for using a micro-abrasive sandblaster and determined how your part will be affected by sandblasting. Next is to determine the type of blasting material you need for your application. There are many types of blasting media used in micro-abrasive sandblasting, but for this article, we will only outline a few. If you’d like more information about different blasting material please call (760) 723-1498 and ask to speak with a sales representative.

- Aluminum Oxide: Aggressive material that will alter the surface. Great for deburring, removing machine lines, and surface abrasion type applications. One side effect of using this blasting material is it tends to embed into the metal, resulting in a grey coloring.

- Sodium Bicarbonate: Aggressive material (less than aluminum oxide) and will alter the surface of softer metals. Great for deburring, removing machine lines, surface abrasion as well as some surface cleaning applications. This material is water soluble which makes for easy cleanup and can be used for most applications. The downside is that it’s not as aggressive as aluminum oxide and could potentially take more time to get desired results.

- Glass Beads: Not aggressive material that will peen surfaces. Great for surface cleaning/polishing and matte finishes. This is a goto for any aesthetic metal finishing application.

Another part of determining the blasting material you’ll need for your metal finishing application is the size. Blasting material can come in a variety of sizes typically between 25-250 microns. You should first determine which media will fit your needs and shoot for the middle, typically 50 microns. If this is too aggressive or not giving you uniform results then reduce it down to 25 microns. If you’re experiencing the opposite problem and need more aggressive, go bigger. Blasting pressure will affect the results as well but should be the last thing you adjust because this will only slightly change your results.

MORE: The Vaniman Guide to Microabrasive Sandblasting Media

Choosing Cabinet Size Based on Application

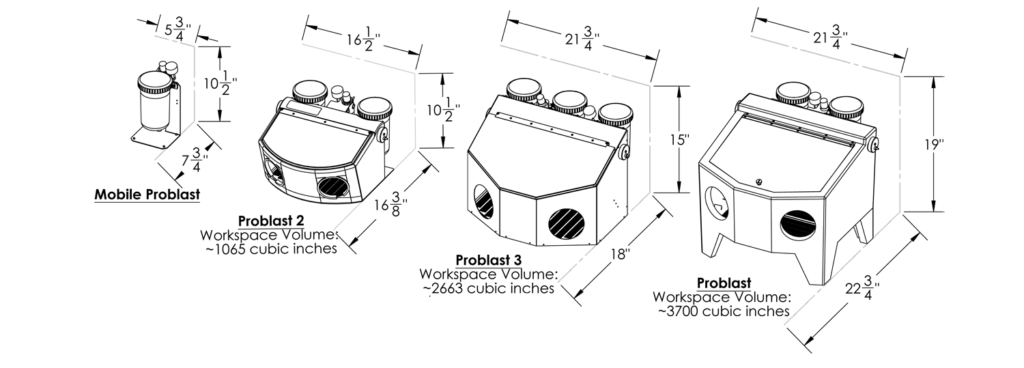

This is pretty straightforward, our largest micro-abrasive sandblasting cabinet is the Master Problast at 22.75”L x 21.75”W x 19”H. If your parts are larger than this you’ll need a custom cabinet. Here’s what we offer:

Instant Off

Some applications require only a small area to be blasted without affecting the rest of the part, such as deburring. For this process, we offer an instant off feature with most of our blaster, which allows for added control during blasting. Stepping on the foot pedal will being the flow and releasing it will stop it instantly. With non-instant off blasters releasing the foot pedal will depressurize the tank causing the media to continue to slow for a short period of time. Applications, where blasting “between the lines” is required, should be done with a blaster equipped with instant off.

Number of Tanks

If you’re working with multiple types of metals and/or have different applications you may want to have multiple tanks. Most of our micro-abrasive sand blasters come with two tanks but we have an option for a third if needed. If you only need one tank then you might as well use the second for the same purpose as the first.

Three Tanks:

Two Tanks:

Dust Collection

Flooding abrasive material with compressed air into a fully enclosed system without any filtration is never a good idea. It will leak out of areas it’s not supposed to which is not good for your health. That’s why we highly recommend using a dust collector. This will not only give the abrasive a blast to go, but it will create a negative pressure inside the cabinet to remove the cloud formed during blasting. Being able to see your work is a good thing. Here is a list of our dust collectors that will pair with any micro-abrasive sandblaster.

Thank you for taking the time to read this blog post. At this point you should have a pretty good idea of how to choose the right micro-abrasive sandblaster for metal finishing. But if you need some additional help please feel free to call and ask to speak with a sales representative at (760) 723-1498 or email us at sales@vaniman.com.